A family-run German haulier is ditching diesel for good and backing up its electric ambitions with a purpose-built depot charging park powered by solar, batteries, and a 4 MW grid connection.

German transport company Nanno Janssen Spedition GmbH is transitioning its fleet to battery-electric vehicles, with 50 of its 75 lorries set to be electric by the end of 2025. The haulage firm has ordered ten Mercedes-Benz eActros 600s, five of which have already entered service, and has built its own depot charging park in Leer, Lower Saxony, to support its long-distance operations.

The company has ruled out the purchase of further diesel trucks, except for routes involving hazardous goods in class 1 (pyrotechnics), which cannot yet be handled by electric vehicles under current regulations.

The new electric fleet is centred on the eActros 600 tractor unit, which features three lithium iron phosphate (LFP) battery packs totalling 621 kWh and offers a real-world range of 500 km. According to Nanno Janssen, who represents the fifth generation of the family-run business, early testing without a trailer recorded consumption of just 60 kWh per 100 km and a display range of 1,000 km.

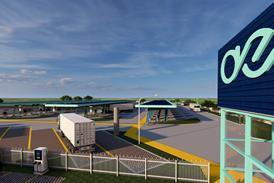

To support depot operations, the company has constructed a 20-bay charging park with a total grid connection of 4 megawatts, supplemented by an 800 kWp solar system and a 1.3 MW battery storage unit. The charging park includes 10 stations, each fitted with two 300 kW charging points. The infrastructure allows staggered recharging to match the company’s national long-haul schedules, with most vehicles not requiring simultaneous charging.

Public infrastructure is also used extensively. During initial handover trips, drivers stopped at the Fastned charging park in Hilden, where the 400 kW car chargers successfully handled the eActros units. Drivers are equipped with apps to locate charging stations offering the best tariffs, with full overnight charging combined with en-route top-ups during breaks.

Janssen began the electrification journey three years ago when the company applied for funding under Germany’s KsNI programme.

“We didn’t do it half-heartedly, we did it right and looked at our entire fleet,” said the younger Nanno Janssen, now executive assistant. “Although we have significantly higher initial costs, we benefit from lower variable costs. This results in approximately the same mileage costs over the entire service life.”

Driver engagement has played a key role in Nanno Janssen’s transition. A five-member team was trained directly at the Mercedes-Benz plant in Wörth am Rhein, ensuring drivers were familiar with the new vehicle technology from the start. Among them was Tobias Wagner ( better known online as the “Electric Trucker”) who has been documenting the company’s shift to battery-electric vehicles for his 60,000 YouTube followers.

![Mercedes-Benz_eActros_600_(1)[1]](https://d2cohhpa0jt4tw.cloudfront.net/Pictures/274x183/8/1/8/17818_mercedesbenz_eactros_600_11_556244.jpg)