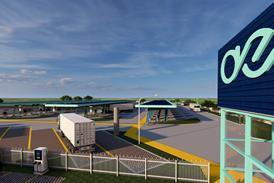

Supporting the drive to decarbonisation: what’s right for your fleet?

For decarbonising HGV fleets, both electrification and hydrogen fuel present viable pathways to achieving zero emissions. The suitability of each depends on factors like fleet size, range requirements, and operating conditions.

You have reached your limit of free news

Register for free today to read more content. Already registered? SIGN IN now

Want to read more?

Register for free now to access the full article.

Let us help you reach your carbon zero targets, sign up today and unlock:

- Unlimited access to breaking news, commentary and analysis around the decarbonisation of the road freight and commercial vehicle sector

- Continued access to the Freight Carbon Zero weekly newsletter, sent directly to your inbox

![Mercedes-Benz_eActros_600_(1)[1]](https://d2cohhpa0jt4tw.cloudfront.net/Pictures/274x183/8/1/8/17818_mercedesbenz_eactros_600_11_556244.jpg)