To many people the name Unipart is associated with the aftermarket parts supplier for British Leyland and later Rover Group, and that is indeed how the company started back in 1974. But today the Unipart Group is a diverse £1bn a year multinational logistics, manufacturing and consulting business working in the automotive, manufacturing, retail and rail industries.

Still based in Cowley, the former home of British Leyland, it is also one of the UK’s largest private companies and over half of the business is owned by its 10,000 employees.

Unipart Logistics is one of three divisions within the group and itself is split into two business units: Unipart Aftermarket Logistics (UAL) whose main client is Jaguar Land Rover (JLR), now owned by Indian conglomerate Tata; and UTL, whose clients include Homebase, Sainsbury's, BSkyB and Vodafone.

Although the Rover brand is still owned by JLR, the remnants of the MG Rover company were sold to the Chinese in 2005 and Unipart no long has any connection with the Rover car parts business.

Unipart Logistics has been a key partner for JLR for over 25 years, running the global aftermarket parts operation serving 850 dealers around the world. Since Tata bought JLR in 2008 for £1.3bn the car maker has gone from strength to strength, reporting record sales of 425,006 vehicles in 2013 - up 19% on 2012. 80% of these were exported with its big markets still being the US, Spain and Germany – though the fastest growing are China, Asia and Russia.

Although Unipart Logistics does not use the term, its operation for JLR has many of the characteristics of a 4PL. It owns and operates a number of large dedicated and shared user DCs on the contract but does not run its own transport fleet.

As a part of the Unipart Group, the Unipart Logistics way of working is the ‘Unipart Way’, a culture of lean process and continuous improvement that aims to eliminate waste and promote efficiency.

“World class is not good enough,” says Bernard Molloy, Unipart Logistics’ global industrial logistics director. “Our culture is one of continuous improvement.”

Our meeting takes place at the 275,000sq ft Baginton A DC near Coventry, where the UAL Global Control Centre is based.

Instant action

The Global Control Centre pulls together real time data on parts availability in any location – including the JLR manufacturing supply chain - enabling instant action to be taken to source that vital part and get it to where it is needed. “This is our own technology and we are constantly upgrading and developing the software,” says Molloy. “It ensures there is only one version of the truth.”

The statistics for Unipart Logistics’ performance on its flagship contract are impressive. It manages 63,000 parts made by 1,200 suppliers through 18 DCs worldwide, filling 100,000 dealer orders every week. It regularly achieves parts 98.6% availability – better than any of its major competitors - and the big screens on the wall of the centre show that out of the 1.2 million JLR vehicles on the road around the world there are just 65 awaiting a spare part.

The culture of continuous improvement at Unipart Logistics is driven bottom up rather than top down and the company positively encourages and rewards innovation from the shop floor. In the corner of the Global Control Centre are bean bags and an ‘innovation tree’ where anyone can come to brain storm and hang new ideas. On the warehouse floor a wall is taken up with an ‘Our Contribution Counts’ display showing the employees who have come up with ideas that have yielded real results.

“We have 85% participation and these ideas have saved £250,000 on this site,” says Simon Dalton, global storage manager at Unipart Automotive Logistics. “We look for the root causes of problems and possible solutions.”

Global hub

Baginton A is the global distribution hub for JLR aftermarket parts. It is supported by a 500,000sq ft global DC and warehouse for slow moving parts at Honeybourne near Evesham, half of which is dedicated to JLR, and feeds satellite regional warehouses in the local markets.

Around 20,000 inbound parts from the UK and overseas are delivered in bulk through a single loading dock every day. A third party haulier – Ebrex – brings one or two consolidated full loads a day from Germany; the rest are delivered by suppliers’ vehicles. The parts are unpacked, and the actual delivery checked against the delivery note. The parts are then individually repacked and place in bins awaiting picking and shipping to dealers.

A P1 priority lane – another ‘Our Contribution Counts’ suggestion - has been introduced to reduce the time taken to process high priority ‘vehicle off road’ parts from 24 to four hours.

Dealer orders are picked using radio frequency barcode scanners, which as well as driving picking accuracy are also used to measure the performance of the operation. “This used to be a daily measure but now we do it every two hours to see if we can improve the next two-hour run,” says Dalton.

Parts go out by road, sea or air depending on the destination and the urgency – where possible the Ebrex vehicles are backloaded with parts destined for German dealers.

Unipart Logistics has also taken on a small manufacturing operation for JLR to help solve a problem with a particular supplier of plastic bumpers. Instead of the supplier handling the whole process, it now just moulds the bumpers and Unipart Logistics punches the holes, assembles them and packs them ready for delivery. Baginton A now handles around 1,200 bumpers a week for JLR.

BSkyB

Just down the road at Baginton B, UTL works just as closely with its major customer BSkyB on the supply of set-top boxes. As well as conventional storage and despatch of 11,000 pallets of product, UTL has invested heavily in machinery to test and repair returned equipment since it started working with BSkyB in 2004, dramatically reducing costs while improving service levels.

Here too the Unipart Way is a key differentiator according to Chris Dixon, director for BSkyB at UTL (pictured).

“The change programme with BSkyB is never ending,” he says. “Best practice means better service at lower cost.”

BSkyB now has 11.5m satellite TV customers in the UK, and while this number continues to grow a key focus for the company is now to offer a top quality aftersales service to viewers who want to upgrade their Sky package or have a fault with their existing set top box.

BSkyB has 2,800 field engineers on the road and UTL ships 20,000 items every day to keep them supplied with everything they need, from set-top boxes to testers, cable and tools.

Pudo

The engineers use a pick up and drop off system, collecting the products they need and dropping off any waste or unwanted items once or twice a week. “Most field stores are in our 170 Unipart Automotive retail outlets,” says Dixon. “We also use ByBox lock boxes.”

A significant proportion of set-top boxes are delivered direct to viewers’ homes when an engineer visit is not required. Deliveries to retail stores or lock boxes are handled by ByBox, with a variety of carriers used for home deliveries.

All returned set-top boxes are examined and tested before a decision is made on whether they can be repaired or recycled, or have to be destroyed. Under the WEEE directive, Baginton B sends nothing to landfill – anything that cannot be reused is returned to the vendor for certified disposal.

In 2011 UTL developed Autotest, a computerised system that can test up to 160 set-top boxes in 42 minutes.

“Before we had to test every box manually with a TV and a remote control,” says Dixon.

Flying Probe

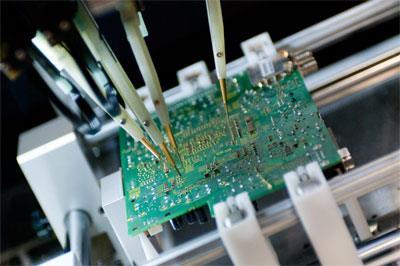

This year has seen another innovation introduced – the Flying Probe (pictured, top). The brains of any piece of electronic kit is the printed circuit board (PCB), which combines hundreds of tiny components, any one of which can fail. Testing PCBs manually is impossibly labour intensive, so in the past faulty boards were simply replaced with a new unit.

The Flying Probe uses a multi-head tester to very rapidly touch and test each component on the PCB – it can check 85% of the components on a set-top box PCB in three minutes.

“The cost of PCBs is rising and we want to reuse them where possible,” says Dixon. “We don’t test with the power on and some faults will only show when they are hot but the Autotest and Flying Probe will find most faults.”

Like Baginton A, the UTL site has an ‘Our Contribution Counts’ wall, which shows 100% participation among staff and £340,000 of savings so far. Also on display are policy deployment charts showing everyone’s responsibilities and priorities from top of UTL down to each business unit.

“Employee engagement is key to high performance,” says Dixon. “Everyone knows our objectives and their role in the business.”